Not only provides a glossy surface, treats metal surfaces and helps remove rust, oxide film, grease or dirt on the metal surface, helping the coating to adhere firmly to the metal surface.

We provide surface treatment solutions applying the most modern technology:

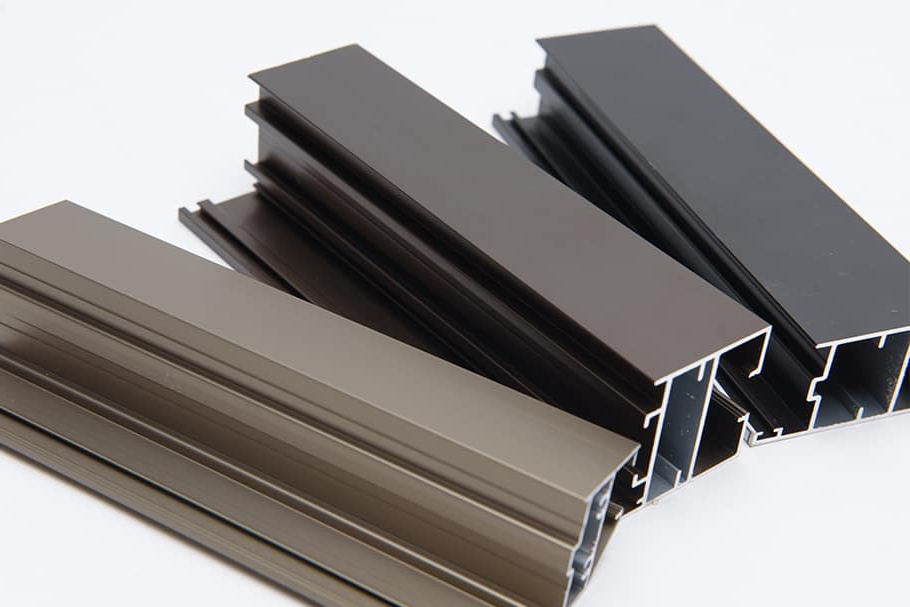

Anode plating - The ultimate treatment for aluminum surfaces.

Surface treatment of products through electrochemical processes to create a stable surface with a certain hardness suitable for use in the industrial field.

Powder Coating Lines.

The process applies electrostatic principles to create an effect between the paint powder and the paint object, thereby coating a plastic layer on the surface of the parts. As a result, the electrostatic coating protects materials from direct contact with the environment, increases longevity, aesthetics, and is suitable for many purposes in the architectural and industrial fields.

Wooden Printing Lines

Wood grain film It is a material that contains all kinds of vein, imitation (artificial) wood surface, we are created by active substances that connect surfaces including 3 main elements, which are the substrate, the film to create the fake texture and the layer. The outermost is guard class.

create a coating to protect the aluminum surface, increase its resistance to environmental impacts, and help create an electrically conductive surface for the product.

With the existing machinery and equipment capacity.

| DEVICES |

|

AMOUNT |

| Melting Facility |

|

6 |

| Aluminum extruders |

|

44 |

| The largest machine size( inches) |

|

12 inch |

| Powder coating lines |

|

7 |

| Anodizing line |

|

3 |

| Liquid Painting line |

|

1 |

| Painted wooden Printing lines |

|

6 |

| Machining to size |

|

|

| Machine CNC |

|

|

| Machining |

Cut |

1 |

| |

Solder |

33 |

| |

Stamping |

21 |

| |

Taroure |

2 |

| |

Drillhole |

10 |

| Assembly line |

|

|

| Design suppor |

|

|

Total Capacity 5000 tons/ month.